Our research

PPT

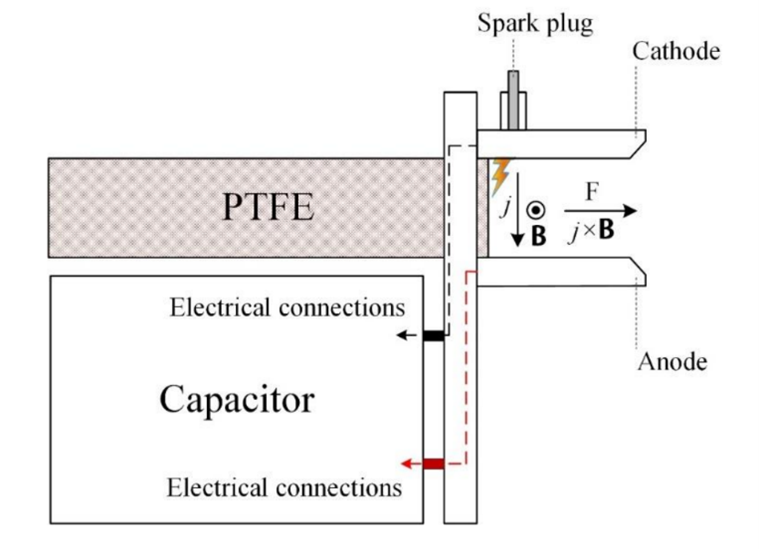

Pulsed Plasma Thruster (PPT) is a kind of electromagnetic thruster in electric propulsion system, but due to the characteristics of PPT instantaneous operation, the effect of thermal expansion acceleration also occupies a certain proportion. Due to the shortcomings of gas PPT, the research on ablative pulsed plasma thruster (APPT) derived from the concept of gas PPT has been continuing until now. APPT is mainly composed of propellant (PTFE), spark plug, anode and cathode, and energy storage capacitor. The figure below shows a schematic diagram of the main components of APPT. The main working process is to charge the energy storage capacitor first, so that a high potential difference (~2000V) is generated between the anode and cathode. Then the spark plug located near the propellant surface sparks to generate a small amount of electrons, which hit the PTFE surface and cause an electron avalanche to trigger an arc between the anode and cathode to generate the main discharge. The main discharge arc ablates and ionizes the PTFE working medium on the surface of the propellant. The ionized plasma is subjected to the mixed effect of the magnetic field of the instantaneous discharge and the electric field between the electrodes between the anode and cathode electrodes, and is accelerated by the electromagnetic force and ejected from the electrodes to generate thrust.

The schematic diagram of ablative pulsed plasma thruster (APPT)

APPT is characterized by its pulsed mode of operation and its use as a solid fluoroplastic propellant. The working mode of the pulse makes APPT have the characteristics of high precision and fast response. The application of solid propellant makes the propellant supply system of APPT very simple and reliable. The solid fuel supply mode driven by constant force spring between parallel plates not only has simple control, high economic benefits, but also improves the payload rate and greatly improves the reliability and life of APPT.

APPT of JLPP

In our laboratory, partitioned anode and short anode structures with higher performance have been developed. At a discharge energy of 20J, the thrust efficiency of APPT increases from 5.3% (conventional anode) to 7.9% (block anode). Compared with conventional anode APPT (i.e. conventional parallel plate electrode), the thrust efficiency is significantly increased by 49%, and the performance parameters (impulse, thrust efficiency, specific impulse, ablation, etc.) of APPT with block anode structure are significantly improved. More gratifying is that the block anode structure size calculation is simple and can be applied to all parallel plate APPT, so it is a simple and effective APPT performance improvement scheme.

The ignition figure of ablative pulsed plasma thruster (APPT)

Featured Articles:

[1] Zhang Z, Ren J, Tang H, William Ling, Thomas M. York, An ablative pulsed plasma thruster with a segmented anode, Plasma sources science and technology, 27(1), 015004, 2018.

[2] Zhang Z, R J, Tang H, Xu S, William Ling, Cao J, Inter-electrode discharge of an ablative pulsed plasma thruster with asymmetric electrodes, Plasma sources science and technology, accepted, 2018.

[3] Zhang Z, Ren J, Tang H, William Ling, Thomas M. York and Cao J, Direct investigation of near-surface plasma acceleration in a pulsed plasma thruster using a segmented anode, Journal of Physics D: Applied Physics, 51(39), 395201, 2018.

[4] William Y L Ling, Zhang Z, Tang H, Liu X, Wang N, In-plume acceleration of leading-edge ions from a pulsed plasma thruster, Plasma sources science and technology, 27(10), 2018.

[5] Zhang Z, et al. The plasma morphology of an asymmetric electrode ablative pulsed plasma thruster, Plasma sources science and technology, 2nd Revision to be published.

(Lastly Updated in September, 2022)